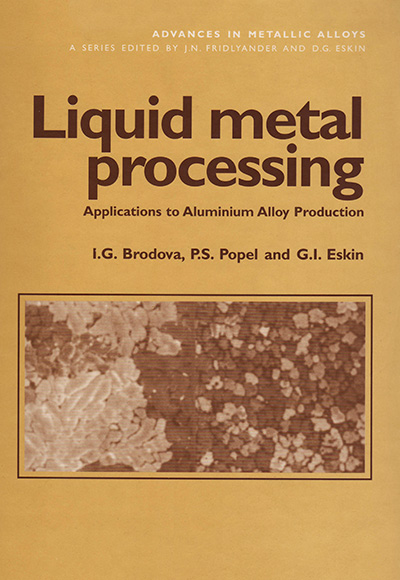

Liquid metal processing. Applications to Aluminium Alloy Production

Авторы: I.G. Brodova, P.S. Popel, G.I. Eskin

Информация о издательстве: London-New York: Taylor & Francis, 2002. – 269 pp.,ISBN 0-415-27233-5

The overwhelming majority of technological processes for producing metallic alloys involve the conversion of initial materials into the molten condition and the subsequent solidification of the system at various, sometimes very high, cooling rates. In an attempt to improve the structure and service properties of ingots, castings and deformed semifinished products, process engineers have paid considerable attention to the search for optimal solidification conditions. The regimes of heat and mechanical treatment of cast metal are progressively improving. Only the first stage of the process - initial melt - is traditionally of marginal interest to metallurgists. In most cases, attempts to affect the system at this stage are confined to additional alloying with the aim of optimizing the system composition, and to refining the system in an effort to remove deleterious impurities.

At the same time a great body of data has been accumulated in scientific periodicals over the past 30-40 years, which indicates that metallic melts are dynamical systems of high complexity. They can exist in different structural states and make transit ons between these states under the influence of various external actions. The role of the structural state of the initial melt in the formation of the structure and properties of ingots produced from this melt and, consequently, the structure and properties of deformed semi-finished products is also established. As applied to steels, cast iron and nickel alloys, these facts are systematized in the collective monograph under the title Liquid Steel * published in the USSR in 1984. However, information regarding aluminium alloys has not been generalized to date, although the data accumulated in this field are equally impressive.

In the authors’ opinion, this monograph may fill this gap. It owes its origin to the collaboration of three researchers who over the past 20-30 years have studied various aspects of interrelation between the structure of aluminium melts am the structure and properties of ingots formed in solidification of these melts, or have searched actively for effective ways of influencing liquid metals to improve the quality of solid metals. We consider in this monograph a few possible ways of governing the structure and properties of cast metal by applying different external actions to the initial melt.

Телеграм канал

Телеграм канал Группа Вконтакте

Группа Вконтакте